spray polyurea, brushable polyurea, pure polyurea, clear polyurea, cold polyurea, viscosity damping material factory

- Home

- About us

-

Products

- Waterproof & Anticorrosive Polyurea

- Vibration & Noise Reduction Damping Material

- Military Defense Polyurea

- Brushable Polyurea

- Speaker Box Decorate Polyurea

- Belt Repair Anti-abrasion Polyurea

- Furniture Decorate Polyurea

- POLYSV Car Armor

- Aliphatic Polyurea

- Heat reflective polyurea

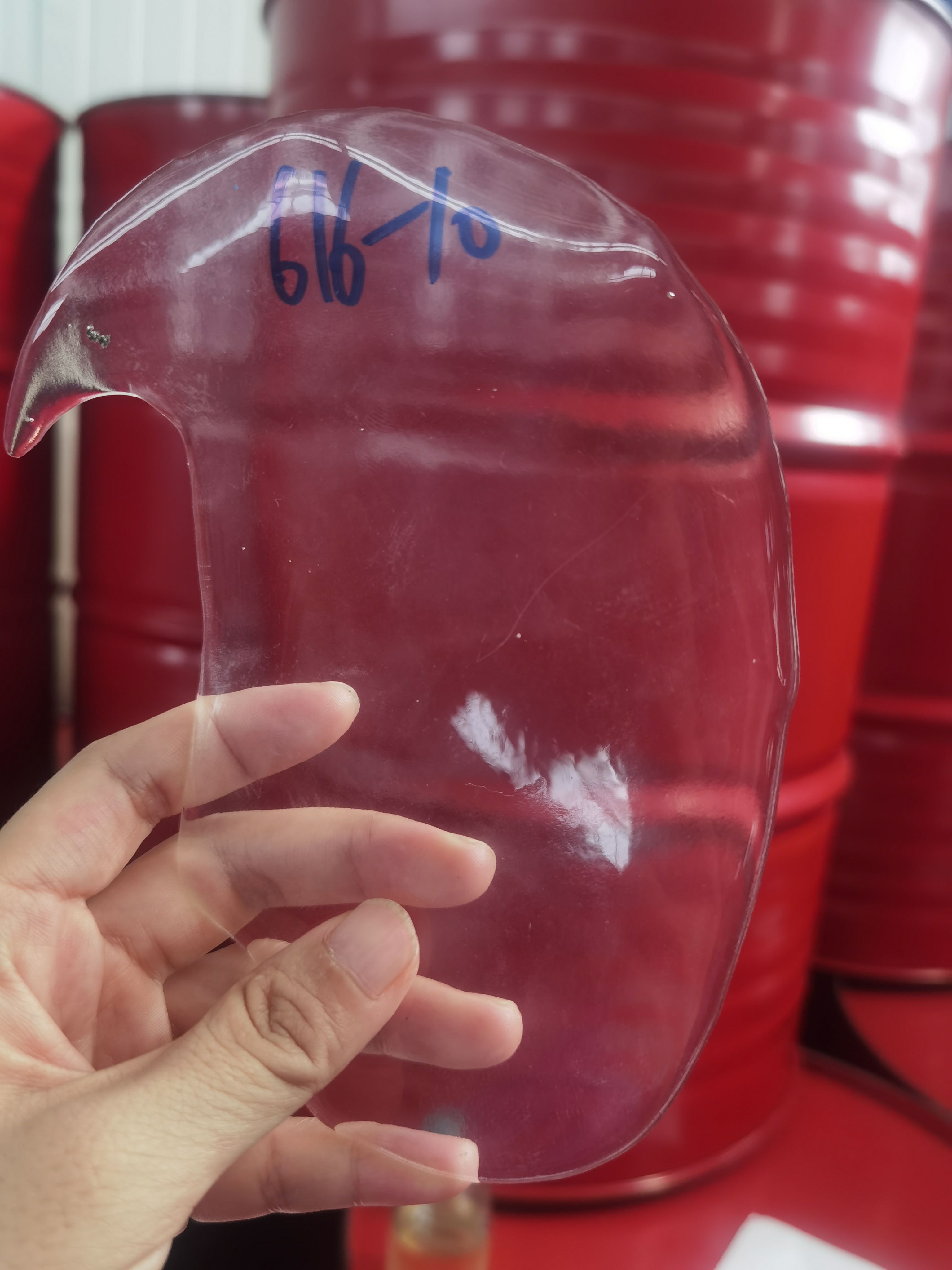

- transparent polyurea

- auxiliary products

- Corollary Equipment

- Applications

-

Technical Data

- How to Choose the Right Primer in Polyurea Projects

- How to Choose the Right Polyurea Spray Equipment

- Sprayed Polyurea VS Hand-Applied Polyurea: A Comparison of Two Application Methods

- How to Calculate the Consumption of Polyurea Coating?

- What Is the Difference Between Aliphatic Polyurea and Aromatic Polyurea?

- Limitations of Polyurea

- Differences Between Pure Polyurea and Hybrid Polyurea

- Maintenance Essentials for Polyurea Spray Equipment

- Can Polyurea Be Bulletproof?

- Do Color-Changing and Non-Color-Changing Polyurea Use Different Pigments?

- Recommendations for Polyurea Application in Humid Seasons

- Impact of Condensation on Construction Quality

- The Importance of an Oil-Water Separator

- The Importance of Putty in Substrate Preparation

- Causes of Pressure Imbalance in Polyurea Spray Equipment

- Polyurea Spray Auxiliary Equipment – Air Compressor

- Auxiliary Equipment for Polyurea Spraying – Refrigerated Air Dryer

- Auxiliary Equipment for Polyurea Spraying – Mobile Application Vehicle

- Application of Polyswell Polyurea Technology in Military Helmets and Ballistic Plates

- Pros and Cons of Single-Component Hand-Applied Polyurea

- Substrate Preparation for Polyurea Coating on Speaker Enclosures

- Application of Polyswell Soft-Feel Polyurea

- Polyswell's Specialized Polyurea for Speaker Enclosures

- The Difference Between Aromatic and Aliphatic Polyurea

- What Is Polyaspartic Polyurea?

- Can Polyurea Be Sprayed with Polyurethane Foam Equipment?

- Pros and Cons of Brushable Polyurea vs. Spray-Applied Polyurea

- Can Polyurea Be Applied on Damp Substrates?

- Main Industrial Applications of Polyurea Technology

- JHSW8601 Polyurea Waterproof and Anti-Corrosion Coating Successfully Passes Food-Contact Coating Standard Testing

- How Are Smooth and Textured Polyurea Surfaces Created?

- The Development History of Polyurea Spray Equipment

- Application of Polyurea Technology on Offshore Drilling Platforms

- Why Are the Temperature Sensor Wires in Polyurea Equipment Prone to Damage?

- Comparison Between Polyurea and Powder Coating

- Why Should the B Component Be Stirred Before Use?

- Why does the spray polyurea in the cold water storage tank always bulge and crack?

- Advantages and Disadvantages of Single-Component and Two-Component Brushable Polyurea

- Classification of Brushable Polyurea

- What is Hand-Applied Polyurea?

- Strength Development Characteristics of Polyurea

- Why Choose Pneumatic Transfer Pumps for Polyurea Spraying Equipment?

- Polyaspartic vs. Epoxy: Which Flooring Coating Reigns Supreme?

- Antistatic Polyurea Introduction

- Spray polyurea for high grade wood speakers

- The Key Points of Fire-retardant Polyurea

- Is Pure Polyurea Color Stable?

- The Influence on Quality of the Storage Stability of A side

- Polyurea for Army Equipements

- Is Hand Applied polyurea the Same as Spray Polyurea?

- Is Polyurea tintable?

- The Influence of Humidity on Polyurea

- What is the Recoat Window of the Primer

- Could Spray Polyurea be Transparent?

- Why Polyurea is Good for Roof Waterproofing?

- Why the Surface should be Dry Before Spray Polyurea

- Why dose Peeling off Occurs?

- How to Control the loss the Spraying Polyurea

- Spray Polyurea used on Foam Sculpture

- How to fix the Bulge

- What is the Difference Between Different Formulation of Polyurea

- How to Calculate the Consumption of Polyurea

- The Importance of Maintains of Polyurea Spray Equipment

- How to Chose a Good Spray Machine?

- What Cause the Crack on Polyurea

- How to Control the Quality of Polyurea

- How to Choose Spray Machine of Polyurea

- How to Avoid the Peeling off of Old and New Layer of Polyurea

- Is the Hardness of Polyurea Adjustable?

- How to Fix Bulges of Polyurea

- Why We should Apply Primer Before Spraying Polyurea

- Quality Control of Spray Polyurea

- How to Identify Pure Polyurea and Hybrid

- Does polyurea really Indestructible?

- Thickness Control of Spray Polyurea

- Standard for polyurea construction of concrete substrates

- Main Advantages of Spray Polyurea Technology

- How to Fill the Pinholes of Polyurea?

- Why Polyurea is Expensive

- The Skills of Spraying Polyurea

- What is the Suggested Spray Thickness of Polyurea

- How to Choose Polyurea Spray Machine?

- Proper Storage of Polyurea Raw Materials

- Spray Polyurea & Single Component Brushable Polyura, Which is Better?

- How long could polyurea last? Can it use over 30 years?

- Polysv Polyurea Technology Protect Army Equipment

- Spray Polyurea Technology on Military Usage

- What Cause the "Bulge" on Polyurea

- How to choose the right top coat for polyurea?

- How to choose flame retardant polyurea

- Polyurea is not always good

- Why should we always seal the A side of polyurea well?

- How are pinholes formed on the sprayed polyurea surface?

- Why does polyurea change color when used outdoors for a long time?

- Why is the color of my polyurea different?

- Why spraying polyurea elastomer technology must use special spraying equipment ?

- What Is Polyurea ?

- Interlayer Overlapping Issues to Watch Out for During Polyurea Construction

- News

- Contact Us

一级标题

一级标题